WHY CHOOSE HOSEJOY?

The real problem isn’t dust collection

It’s the lack of a system.

Dust-collection fittings aren’t standardized. A “2 inch” or “4 inch” label doesn’t guarantee anything will actually fit. Most connectors are designed to be universal, which means every connection becomes a workaround.

- Hoses that fall off or need constant adjustment

- Air leaks that reduce system performance

- Different connection methods on every tool

When each tool is handled differently, the shop slows down. Dust collection becomes something you manage instead of something that just works.

How It Works

HoseJoy turns dust collection into a consistent, shop-wide system.

The goal is simple: every tool connects the same way, airflow stays strong, and nothing needs constant adjustment.

What Makes the System Work?

Consistent Fit

Matched connectors create repeatable connections across your shop.

Fast, Secure Connection

Powerful magnets pull the connection into place and hold it there—no clamps, no fiddling.

No Airflow Loss

Internal diameters stay true to the tool port, helping preserve airflow and suction.

Expandable & Customizable

Standard connectors cover most tools, and custom parts bring non-standard or legacy machines into the same system.

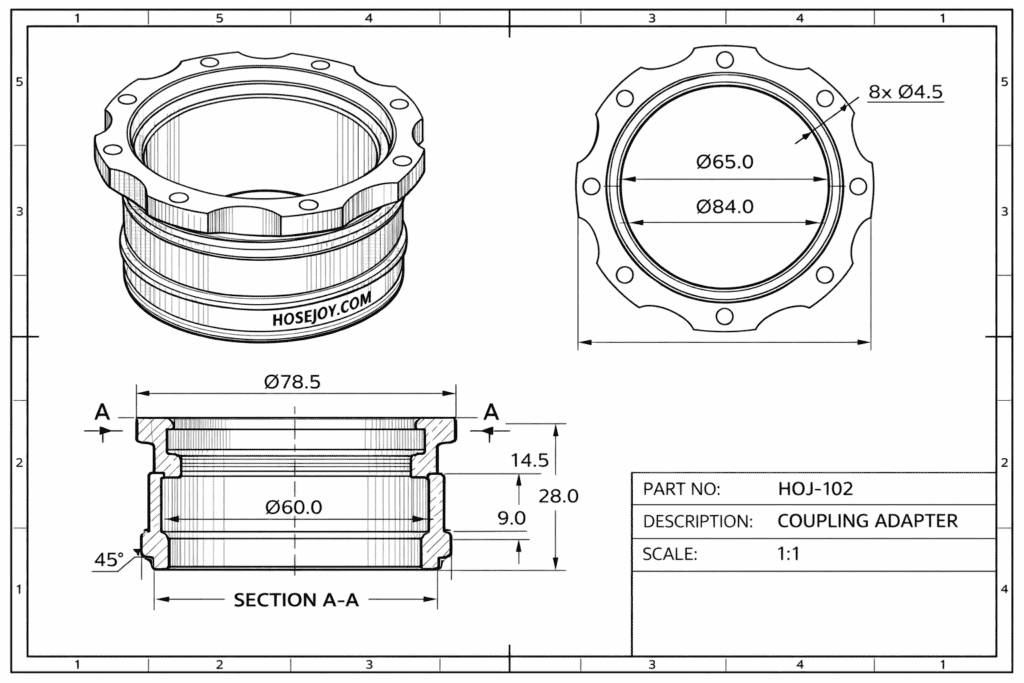

Custom Connectors

When a Standard Connector Isn’t Enough

Some tools don’t fit cleanly into a catalog. Older machines, specialty equipment, or modified ports are common.

When that happens, we design custom HoseJoy parts to bring those tools into the same system—so nothing gets left out.

Built to last in real shops

HoseJoy components are designed and manufactured in the USA and built for daily use. These aren’t disposable fittings. They’re durable shop tools meant to hold up over time.

We back them with a limited lifetime warranty because a system only works if you can rely on it.